“My computer won’t read my CDs”, said my darling wife. Her computer is a relic, but I was hoping that it would last until 2012. She wanted to put songs from Xmas CDs onto her iPod.

I’ve only ripped a CD on rare occasion, and I dislike iTunes, so I was not familiar with this. I reviewed the steps involved. Her process seemed hunky dory. I next wanted to look inside the computer case. As I’ve done many times before, in countless circumstances over he last three decades, I took off the computer’s cover to see what’s up. This has always been a harmless procedure. Not today.

This computer is in a dark cubby hole underneath the office desk. I crawled under the desk and removed the side cover. As I brushed my hand against a ribbon cable, a spark, for the briefest instant, illuminated the inside of the computer case. Then all was dark and silent. SOMETHING was wrong. Time was running out.

Luckily, I had a spare power supply. I swapped the power supply. Nothing. I was about to panic. Instead, the wisdom of age prevailed. I ripped the CD to iTunes on my PC and then downloaded the music via CopyTrans to her iPod nano. With that crisis averted, I had one crisis left: the wife’s dead PC.

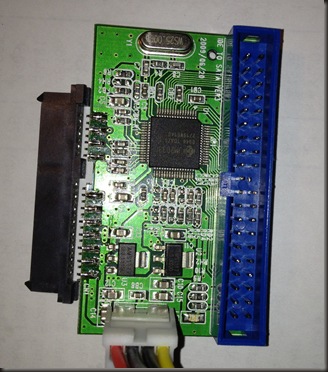

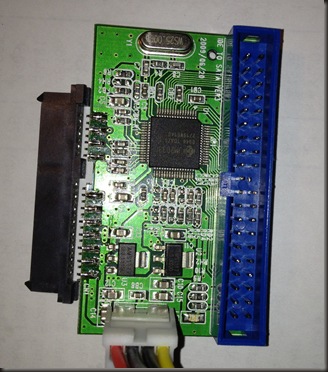

Let me tell you about our computer set up. We have two nearly identical PCs. I built them up in 2003 or so for gaming. Back in their day they were fast machines. Time and technology marches on – these machines are showing their age. For example a few months ago I put a new HDD into her computer. I discovered that IDE HDDs are becoming a rarity. I got her a 500GB SATA drive. Needed an adaptor to make it work.

For our nearly identical PCs, the sameness applies to the Mother Board, the CPU, the case, the memory and the video card. So they’re really a little bit different. One difference that I don’t quite understand is that on my PC, switching the rear power switch ON is all that’s needed to start the PC. On hers, one must switch the rear switch AND then press the front reset switch. So in my haste I feared that her power supply failed. Not so.

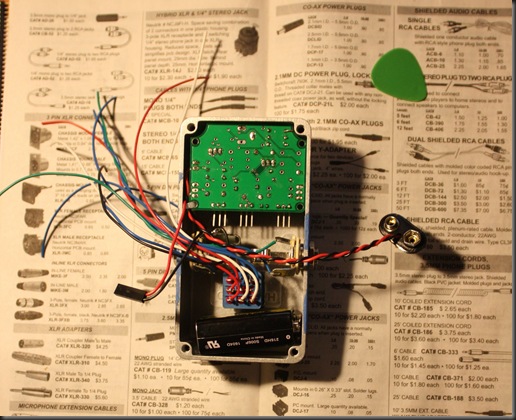

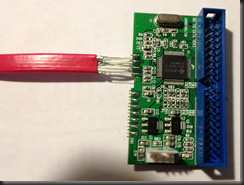

I went out for the day. By the time I got back to troubleshooting her computer, I was confident that the power supply was ok. I next checked her HDD. I put the drive into my computer. While installing the drive, the drive’s IDE to SATA adaptor crumbled in my hand. As I said these are old machines. When I recently rescued her computer from a drive failure, the only viable choices were SATA drives.

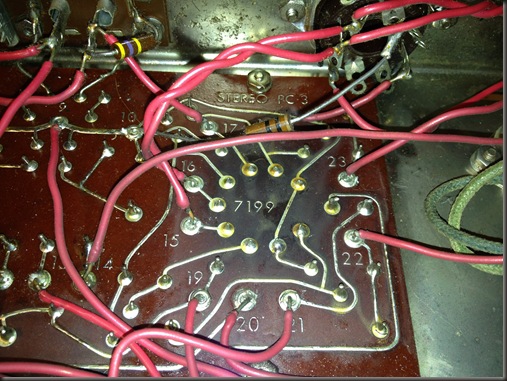

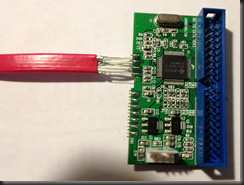

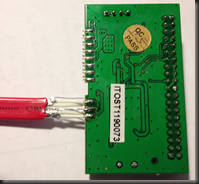

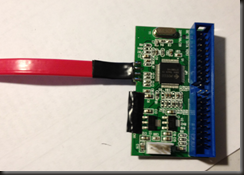

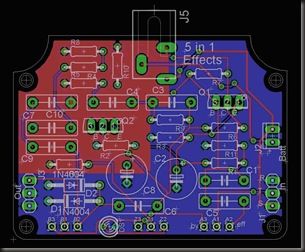

When I installed this set up, the adaptor worked great, although its mechanical construction was flimsy. The SATA connector on this device is a through-hole connector repurposed as an edge connector. In the photo above you’ll see that the connector is no longer attached to the motherboard.

As verified each component of the computer, one by one. The only failure, it turned out, was the SATA to IDE adaptor. That was good news, however, soldering those 20-plus contacts would be impossible, and my dear wife was anxious to use her computer. What to do?

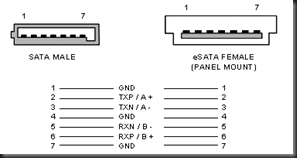

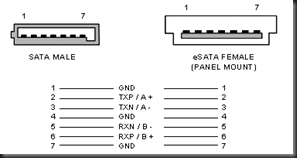

At some point I noticed that the big section of the connector was for SATA power. Power is easy to come by, so this part of the connector seemed unnecessary. The smaller section of the connector is SATA data. I Googled SATA data and took a quick primer on all things SATA. SATA data is a pretty clean high speed bus. It is composed of 7 signal connections. The seven wires are: two differential pairs (in and out) and three ground connections. However, soldering the original connector back into place was just too difficult.

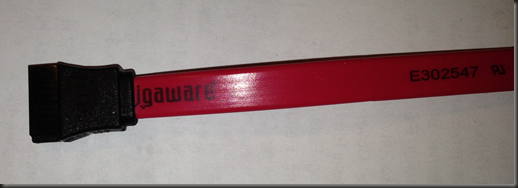

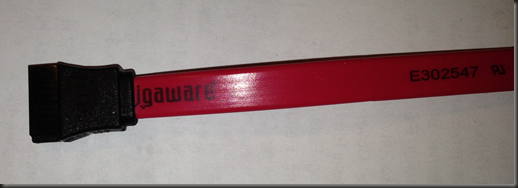

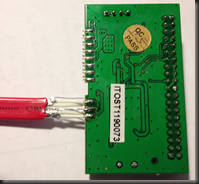

I surmised that the transceiver on the adaptor could carry the signal past the original connection point by a few more inches without problem. I would solder cable end in place of the original connector. I ran to radio Shack and bought a SATA data cable. Once I was back home, I cut the cable in half and prepared the wires.

It’s a flat cable so it was a breeze to verify the proper pin out. The cable jacket was elegant. Each twisted pair was in its own section wrapped in foil with two ground wires.

I connected everything 1 to 1, save for pin 4, where I connected two ground wires, one each from the two twisted pair bundles. With a little bit of electrical tape to protect from shorting, I was ready to roll.

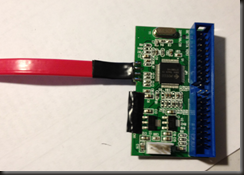

I plugged the IDE cable into the adaptor, as well as a power cable. On the drive, I plugged in a SATA power cable from the power supply harness and the SATA data cable end that I had soldered onto the adaptor board. I powered up the computer. It booted up and has run fine ever since.

I now know a lot more about SATA and once again, I performed some intense hardware surgery and the patient survived!

Posted in Uncategorized